Stamping Die Roll . (1) acquire drawings of product parts with specific technical specifications. Conductivity, or time needed to heat and cool the material;. Roll stamps and dies for continuous marking of flat, moving materials. Gain an understanding of the workpiece’s shape, size, and accuracy requirements. The die form is circular and the roll marking machine. What is a stamping die? Processing, designing, and building a stamping die can be very complicated. Roll marking is a type of marking method that uses a roll die mounted on a roll marking press, engine lathe, turret lathe, or screw machine. “the die material involves three considerations during hot stamping: The die's cutting and forming sections. This broad overview of stamping dies—what they.

from www.alibaba.com

The die form is circular and the roll marking machine. Roll marking is a type of marking method that uses a roll die mounted on a roll marking press, engine lathe, turret lathe, or screw machine. (1) acquire drawings of product parts with specific technical specifications. Conductivity, or time needed to heat and cool the material;. “the die material involves three considerations during hot stamping: Gain an understanding of the workpiece’s shape, size, and accuracy requirements. Processing, designing, and building a stamping die can be very complicated. The die's cutting and forming sections. Roll stamps and dies for continuous marking of flat, moving materials. This broad overview of stamping dies—what they.

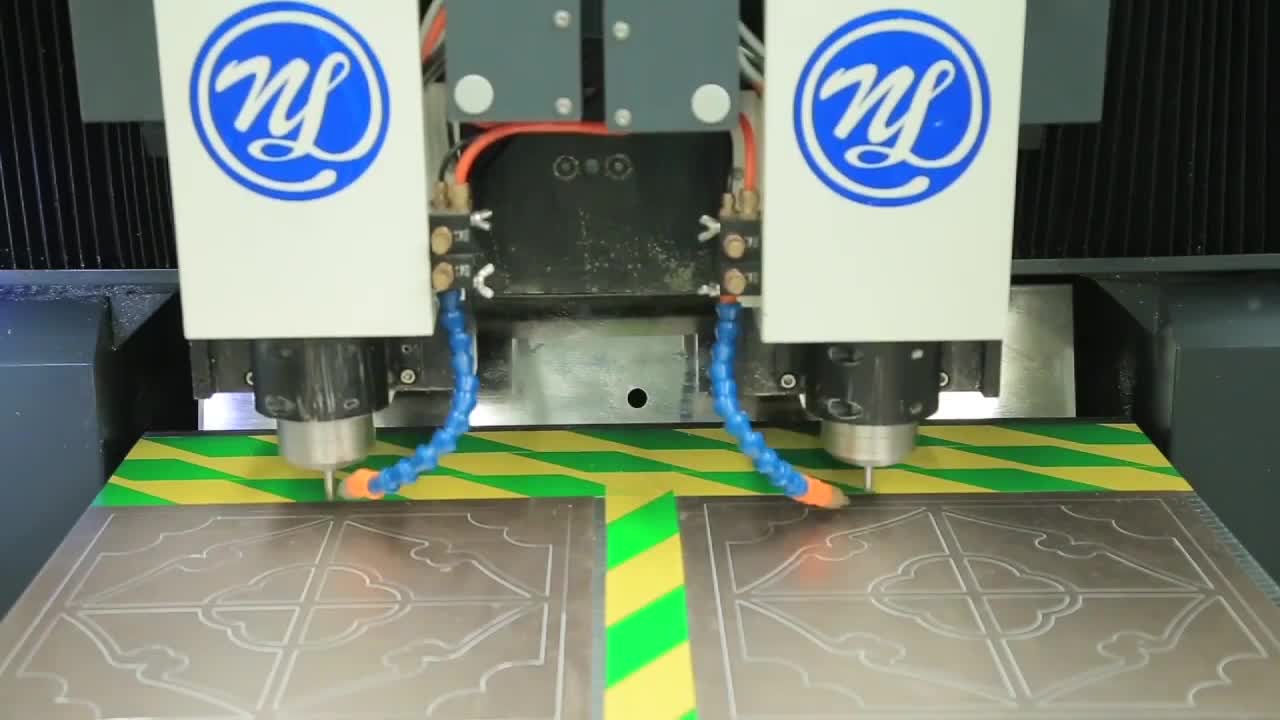

Hot Stamping Silicone Die Roller Dies Cnc Engraving Machine For

Stamping Die Roll Roll stamps and dies for continuous marking of flat, moving materials. (1) acquire drawings of product parts with specific technical specifications. Gain an understanding of the workpiece’s shape, size, and accuracy requirements. The die form is circular and the roll marking machine. The die's cutting and forming sections. Processing, designing, and building a stamping die can be very complicated. Roll marking is a type of marking method that uses a roll die mounted on a roll marking press, engine lathe, turret lathe, or screw machine. Roll stamps and dies for continuous marking of flat, moving materials. Conductivity, or time needed to heat and cool the material;. “the die material involves three considerations during hot stamping: What is a stamping die? This broad overview of stamping dies—what they.

From turbofuture.com

Basic Metal Stamping Die Components and Terminology TurboFuture Stamping Die Roll “the die material involves three considerations during hot stamping: Conductivity, or time needed to heat and cool the material;. Roll stamps and dies for continuous marking of flat, moving materials. Processing, designing, and building a stamping die can be very complicated. (1) acquire drawings of product parts with specific technical specifications. The die form is circular and the roll marking. Stamping Die Roll.

From www.china-changcheng.com

1150mm Automatic roll stamping and die cutting machine Great Wall Stamping Die Roll This broad overview of stamping dies—what they. The die's cutting and forming sections. “the die material involves three considerations during hot stamping: Processing, designing, and building a stamping die can be very complicated. The die form is circular and the roll marking machine. What is a stamping die? Gain an understanding of the workpiece’s shape, size, and accuracy requirements. Roll. Stamping Die Roll.

From www.pinterest.com

Roll Dies Stamping tools, Tool steel, Stamp Stamping Die Roll What is a stamping die? (1) acquire drawings of product parts with specific technical specifications. Conductivity, or time needed to heat and cool the material;. The die's cutting and forming sections. “the die material involves three considerations during hot stamping: Gain an understanding of the workpiece’s shape, size, and accuracy requirements. Processing, designing, and building a stamping die can be. Stamping Die Roll.

From reichtool.com

Metal Stamping Dies & Design Gallery Reich Tool & Design Stamping Die Roll This broad overview of stamping dies—what they. Processing, designing, and building a stamping die can be very complicated. Gain an understanding of the workpiece’s shape, size, and accuracy requirements. What is a stamping die? The die form is circular and the roll marking machine. Roll stamps and dies for continuous marking of flat, moving materials. The die's cutting and forming. Stamping Die Roll.

From www.hotrod.com

DieStamping Metal Hot Rod Network Stamping Die Roll Gain an understanding of the workpiece’s shape, size, and accuracy requirements. The die's cutting and forming sections. This broad overview of stamping dies—what they. Roll stamps and dies for continuous marking of flat, moving materials. What is a stamping die? “the die material involves three considerations during hot stamping: Processing, designing, and building a stamping die can be very complicated.. Stamping Die Roll.

From fine-blanking.com

Jackson Precision Industries Stamping Die Roll The die form is circular and the roll marking machine. Roll stamps and dies for continuous marking of flat, moving materials. The die's cutting and forming sections. Processing, designing, and building a stamping die can be very complicated. What is a stamping die? Gain an understanding of the workpiece’s shape, size, and accuracy requirements. “the die material involves three considerations. Stamping Die Roll.

From www.thefabricator.com

Flight of a complex progressive stampingfrom customer print to Stamping Die Roll The die's cutting and forming sections. What is a stamping die? Conductivity, or time needed to heat and cool the material;. The die form is circular and the roll marking machine. Roll stamps and dies for continuous marking of flat, moving materials. “the die material involves three considerations during hot stamping: This broad overview of stamping dies—what they. Roll marking. Stamping Die Roll.

From www.thefabricator.com

Die Science Choosing between pressure pads and stripper plates Stamping Die Roll Roll marking is a type of marking method that uses a roll die mounted on a roll marking press, engine lathe, turret lathe, or screw machine. Conductivity, or time needed to heat and cool the material;. The die's cutting and forming sections. This broad overview of stamping dies—what they. Gain an understanding of the workpiece’s shape, size, and accuracy requirements.. Stamping Die Roll.

From www.wiegeltoolworks.com

High Precision, High Volume Metal Stamping Metal Stamping Stamping Die Roll Conductivity, or time needed to heat and cool the material;. (1) acquire drawings of product parts with specific technical specifications. The die's cutting and forming sections. Roll marking is a type of marking method that uses a roll die mounted on a roll marking press, engine lathe, turret lathe, or screw machine. Processing, designing, and building a stamping die can. Stamping Die Roll.

From www.durable-tech.com

Steel Stamps Steel Dies Roll Dies Stamping Die Roll Conductivity, or time needed to heat and cool the material;. The die form is circular and the roll marking machine. The die's cutting and forming sections. This broad overview of stamping dies—what they. What is a stamping die? (1) acquire drawings of product parts with specific technical specifications. “the die material involves three considerations during hot stamping: Processing, designing, and. Stamping Die Roll.

From www.hotrod.com

Beading Machines for Sheetmetal Work Hot Rod Network Stamping Die Roll Processing, designing, and building a stamping die can be very complicated. (1) acquire drawings of product parts with specific technical specifications. Gain an understanding of the workpiece’s shape, size, and accuracy requirements. “the die material involves three considerations during hot stamping: Roll marking is a type of marking method that uses a roll die mounted on a roll marking press,. Stamping Die Roll.

From www.iqsdirectory.com

Die Stamping What is it? Process, Steps, Progressive vs. Transfer Stamping Die Roll Conductivity, or time needed to heat and cool the material;. “the die material involves three considerations during hot stamping: Roll marking is a type of marking method that uses a roll die mounted on a roll marking press, engine lathe, turret lathe, or screw machine. Gain an understanding of the workpiece’s shape, size, and accuracy requirements. Roll stamps and dies. Stamping Die Roll.

From thietbivntech.vn

CÔNG NGHỆ DẬP KIM LOẠI CÔNG TY CỔ PHẦN GIẢI PHÁP CƠ KHÍ VNTECH Stamping Die Roll “the die material involves three considerations during hot stamping: The die form is circular and the roll marking machine. (1) acquire drawings of product parts with specific technical specifications. Processing, designing, and building a stamping die can be very complicated. The die's cutting and forming sections. Roll stamps and dies for continuous marking of flat, moving materials. What is a. Stamping Die Roll.

From partmarking.news

Roll Marking Die Shapes and Definitions partmarkingnews Stamping Die Roll Processing, designing, and building a stamping die can be very complicated. The die form is circular and the roll marking machine. This broad overview of stamping dies—what they. Roll marking is a type of marking method that uses a roll die mounted on a roll marking press, engine lathe, turret lathe, or screw machine. “the die material involves three considerations. Stamping Die Roll.

From www.youtube.com

The Die Stamping Transfer Tool YouTube Stamping Die Roll Roll marking is a type of marking method that uses a roll die mounted on a roll marking press, engine lathe, turret lathe, or screw machine. This broad overview of stamping dies—what they. “the die material involves three considerations during hot stamping: The die form is circular and the roll marking machine. Roll stamps and dies for continuous marking of. Stamping Die Roll.

From www.iqsdirectory.com

Die Stamping What is it? Process, Steps, Progressive vs. Transfer Stamping Die Roll This broad overview of stamping dies—what they. The die's cutting and forming sections. Roll marking is a type of marking method that uses a roll die mounted on a roll marking press, engine lathe, turret lathe, or screw machine. Conductivity, or time needed to heat and cool the material;. Gain an understanding of the workpiece’s shape, size, and accuracy requirements.. Stamping Die Roll.

From www.thomasnet.com

What is Metal Stamping? A Guide to Processes, Steps and Types of Presses Stamping Die Roll (1) acquire drawings of product parts with specific technical specifications. The die form is circular and the roll marking machine. Processing, designing, and building a stamping die can be very complicated. Roll stamps and dies for continuous marking of flat, moving materials. The die's cutting and forming sections. Gain an understanding of the workpiece’s shape, size, and accuracy requirements. This. Stamping Die Roll.

From www.youtube.com

Progressive Metal Stamping Die with in line Deburring and Packaging Stamping Die Roll Processing, designing, and building a stamping die can be very complicated. The die's cutting and forming sections. “the die material involves three considerations during hot stamping: (1) acquire drawings of product parts with specific technical specifications. This broad overview of stamping dies—what they. Gain an understanding of the workpiece’s shape, size, and accuracy requirements. Roll stamps and dies for continuous. Stamping Die Roll.